You are here

AA cell discarge anaylsis using the Arduino and GNUPlot.

Download the Arduino sketch and bash scripts for use with GNUPlot here:

Tar format: Arduino_battery_tester.tar.gz MD5Sum: ce0ed75b489310d1494745310d09d8bb

Zip format: Arduino_battery_tester.zip MD5Sum: 482afffb6ec819d5c826c5019dad512b

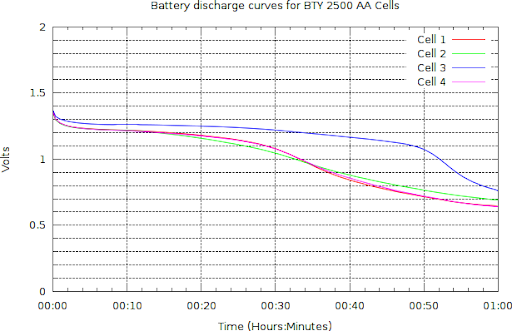

The discharge current for all tests is 400mA at 1.1V A constant current discharge circuit would have advantages. Producing a sharper fall-off curve. But the relative results obtained here are valid indicators of duds.

Take a look at the cells under test................

Discharge test result:

Tried charging these cells again. The charger rejected all attempts to charge these cells now.

I still ran the discharge test again but swapped the order of cells just to verify the

one relatively good (but still pants) cell:

The cells under test:

Discharge test result:

Notice the rise in voltage at the start. These cells do get warm and I suspect the initial rise in temperature increased cell output.

The cells under test:

Discharge test result: